Nonwovens: Current Trends and OpportunitiesNonwovens: Current Trends and Opportunities

The fate of nonwovens vows to be intriguing and possibly exceptionally fulfilling

While the nonwoven and material businesses share some normal legacy, the nonwoven business has developed to introduce a wide cluster of designed fiber and polymer-based items that are driven by rapid, minimal expense, imaginative, esteem added measures. The nonwoven business made an environment that is based on mechanization, decreasing the reliance on minimal expense work — henceforth, the business has not needed to set up assembling offices in low-work cost locales on the planet. Nonwovens are commonly made and changed over where they are sold in this manner limiting transportation costs.

The business has adjusted innovations from the mash and paper, and expulsion enterprises, for instance, to make the ideal items at sensible expense. Mechanized changing over has been a significant piece of the nonwoven store network for a long time, and today, the business can create more than 1,000 diapers each moment.

Unmistakably, rapid, huge volume and low unit cost of creation requests full robotization. This thusly, implies that short runs and adaptability in contributions becomes restricted.

The present nonwoven portions of the business incorporate crude material providers, roll merchandise makers, the converters/fabricators of the end use items, a hardware industry supporting the past three classifications, helper material providers, winding, cutting, bundling gear producers, among different fragments. This rundown doesn’t offer as clear an image as one would envision, in light of the fact that the image is additionally obfuscated by changing levels of vertical and even mix inside the business. Universally, the image is additionally muddled by the neighborhood market and monetary subtleties.

What is clear in any case, is that the nonwovens business keeps on being versatile, imaginative and tirelessly shrewd. This implies that in the prompt a long time to come, there might be a variety of items that can supplant more customary materials — some might see this a chance, while others might consider this to be a danger.

Manageability

While a transition to reasonable creation is incompletely determined by guidelines and tax assessment, the nonwoven business has consistently been at the bleeding edge driving the charge for maintainability. At ITMA 2015, maintainability was one of the significant topics that ruled a portion of the instructive meetings, conversations and grants. The subject likewise was clear in the topics introduced by various key producers. For the most part, the nonwovens exhibitors at ITMA 2015 had some level of spotlight on maintainability.

Words like supportability, reuse, diminish and reuse, are more than popular expressions in the nonwovens world, they are genuine. Add to these words likewise rehash. Given full scale drifts worldwide, rehash of existing items and cycles is more genuine than any other time in recent memory.

In January 2018, the European Commission embraced the world’s first far reaching Plastics Strategy. In May, the commission delivered “The Single-Use Plastics: New Measures to Reduce Marine Litter” report, which proposed new standards to diminish the 10 most discovered plastic waste things on Europe’s sea shores that record for 43% of all out marine litter.

The 10 things are:

- Cotton buds;

- Cutlery, plates, straws and stirrers;

- Sticks for inflatables and inflatables;

- Food compartments;

- Drink cups;

- Drink holders;

- Cigarette butts;

- Plastic transporter packs;

- Fresh parcels and candy coverings; and

- Moist disposable clothes and sterile things.

The activities prescribed to decrease this waste incorporates:

- Boycott — supplant with maintainable other options;

- Instruction and broadened maker obligation (EPR);

- Decrease of utilization;

- Expanded reusing endeavors;

- New naming to empower appropriate removal; and

- Upgrade.

This prohibition on single-use plastics has effectively affected the nonwoven business. Thing 10 on the rundown, the nonwoven moist disposable clothes and sterile things, were exposed to EPR. This is an arrangement approach that expands the maker’s obligation regarding an item past the current extension — for specialist wellbeing and security, shopper security and creation costs — to likewise incorporate administration of item after the item has been utilized by buyers. EPR arrangements by and large shift the waste administration cost or actual assortment to some extent or completely from nearby governments to makers. Approaches can likewise include motivating forces for makers to consider natural contemplations when planning their items.

EPR was first spearheaded in Europe over 20 years prior. From that point forward, by far most of European Union Member States have presented EPR for bundling.

EPR isn’t a possibility for such items as child wipes and sterile items. These items are made utilizing a combination of cellulose and a man-made fiber like polyester (PET) or polypropylene (PP), and are delivered generally utilizing checking and hydroentangling strategies.

Conforming to the European Union decision requires an alternate answer for moist disposable clothes and sterile things. The nonwovens business offers options for creating manageable wipes and different items. For instance, a significant advancement was offered by Austria-based Andritz AG. The superior Wetlace™ measure for flushable, dispersible, and biodegradable wipes was exhibited back in 2015. Also, Germany-based Trützschler Nonwovens GmbH, in a joint effort with The Voith Group, Germany, offers arrangements that can supplant existing fossil-based polymeric fiber items with cellulose and other bio-based polymers, for example, polylactic corrosive (PLA) to conquer the EU boycott.

These cycles can create wipes by consolidating wetlaid and hydroentanglement advancements demonstrated to delivering nonwovens and nonwoven clears off of 100% normal as well as sustainable crude materials without synthetic covers. The cycles additionally extend the scope of expected contributions permitting carbon and glass to likewise be prepared on a similar hardware.

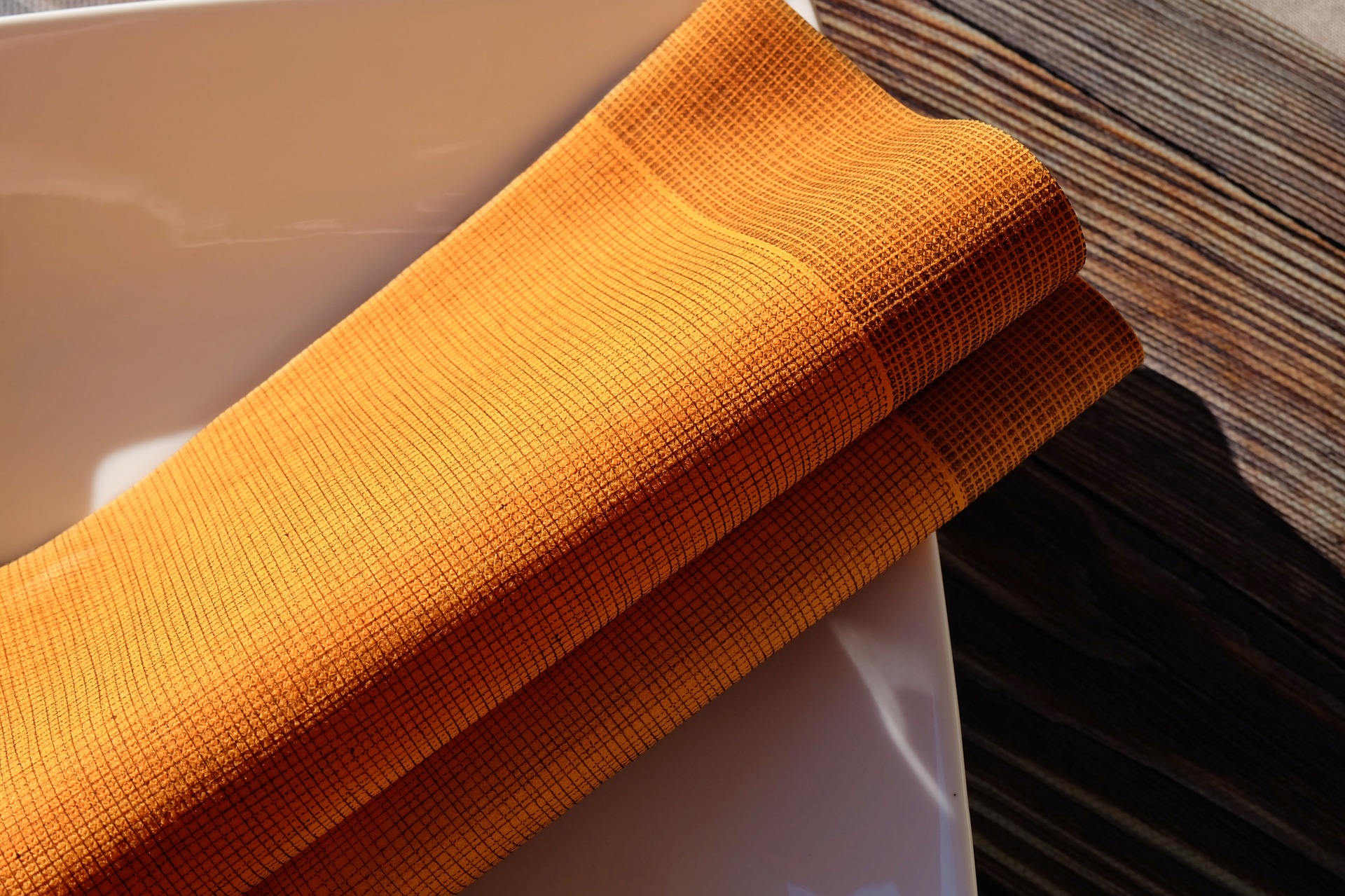

Designing permits makers to separate their items plainly with a practically limitless number of potential examples. An illustration of a 100% cellulose based flushable wipe highlighting interesting work of art is displayed in Figure 1.

These wetlaid/hydroentangled measures are financially reasonable in that they have a lot higher throughput than the current checking/hydroentangling frameworks they are supplanting. While capital expenses might be higher, the absolute framework cost is lower in view of the greater throughput and this ought to mean no increment in cost to the buyer. Undoubtedly, it might bring about lower all out unit cost if the volumes are sufficiently huge — and for the business sectors of interest, they without a doubt are.

Another significant space of center is reuse. There is huge industry action around zero waste just as reusing. This is really difficult for ventures, for example, the nonwovens business where huge volume creation additionally implies enormous volume edge trim and other waste. Reuse will be a significant space of center for some organizations. Exercises will zero in on discovering new applications for such waste or complete reuse of a similar item. The test will be with blended materials and furthermore bicomponent fiber reusing/reuse. New methodologies, new compatibilizers and new sciences will be expected to reuse blended materials.

There will be additionally considerably more critical spotlight on the utilization of biopolymers like PLA, polyhydroxyalkanoate (PHA), polyhydroxybutyrate (PHB), and their mixes, and whenever the situation allows, cellulose strands. All things considered, an age of new items will supplant the current best in class. One key is that these new materials need to likewise be monetarily reasonable — today, the business has numerous supportable arrangements that are not yet financially feasible and that will stay a test except if guidelines and tax collection offset the material expenses. In the more specialty advertises, these new bio-accommodating items will show up first, as was seen with the PLA-based espresso/tea bags and single-use espresso units.